Škoda Auto designers have once again shown their “simply clever” in the HiPE project.

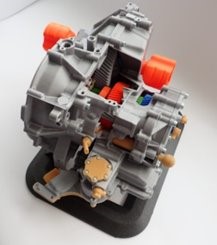

As part of the development of a multi-stage gearbox for electric cars, Škoda Auto engineers made the most of the possibility of 3D printing of the gearbox model in 1:2 scale. This solution has allowed them to reduce development loops and thus the transmission development cycle. 3D printing has enabled practical verification of the assembly ability of parts and the quick definition of potential risks that would otherwise only appear during the assembly and production of real parts. This has led to both – cost optimization and elimination potential time loss of the project.